Professor Hua Lin's team from the School of Automotive Engineering at Wuhan University, in collaboration with Professor Zhang Laichang of Edith Cowan University in Australia, published a review article, "Electromagnetic treatment enhancing performance of metal materials: A review, 153(2025)101488. in the international academic journal Progress in Materials Science (IF=33.6).

This is the first time the team has summarized nearly two decades of research findings and provided a detailed overview and outlook on the connotation, research ideas. and research progress in and around the world regarding electromagnetic treatment. Wuhan University of Technology is the first completing and first corresponding institution for the paper, with Professor Xie Lechun and doctoral student Sun Hongxin as co-first authors, and Professor Hua Lin and Professor Zhang Laichang as co-corresponding authors.

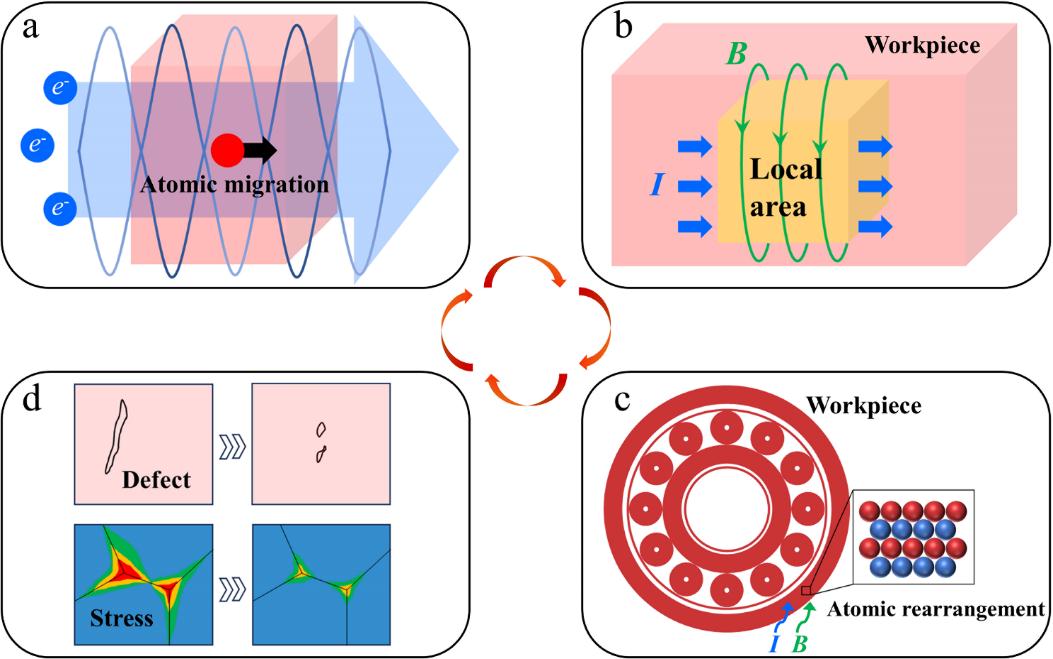

Electromagnetic processing technology (including electric field, magnetic field and electromagnetic field coupling processing) can achieve atomic-scale energy transfer through high transmission rate and high energy flux density, so as to regulate the microstructure and mechanical properties of materials. At present, electromagnetic treatment technology has been applied in industry, but its mechanism and system research are not perfect. This paper summarizes the various effects of electromagnetic treatment, such as energy transfer and action, targeting. extreme spatiotemporal scale characteristics, defect repair effects, etc., as shown in Fig. 1, and reveals the mechanism of electromagnetic treatment through thermal and non- thermal effects.

Figure 1. Characteristics of Electromagnetic Treatment

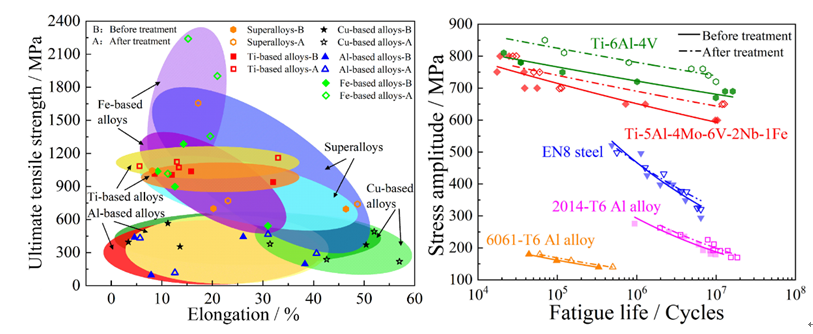

Electromagnetic treatment technology can precisely control the microstructural characteristics of metal materials, effectively improving residual stress and corrosion resistance, and significantly enhancing wear resistance, impact toughness, and fatigue resistance, as shown in Figure 2.

Figure 2. Comparison of material properties before and after electromagnetic treatment

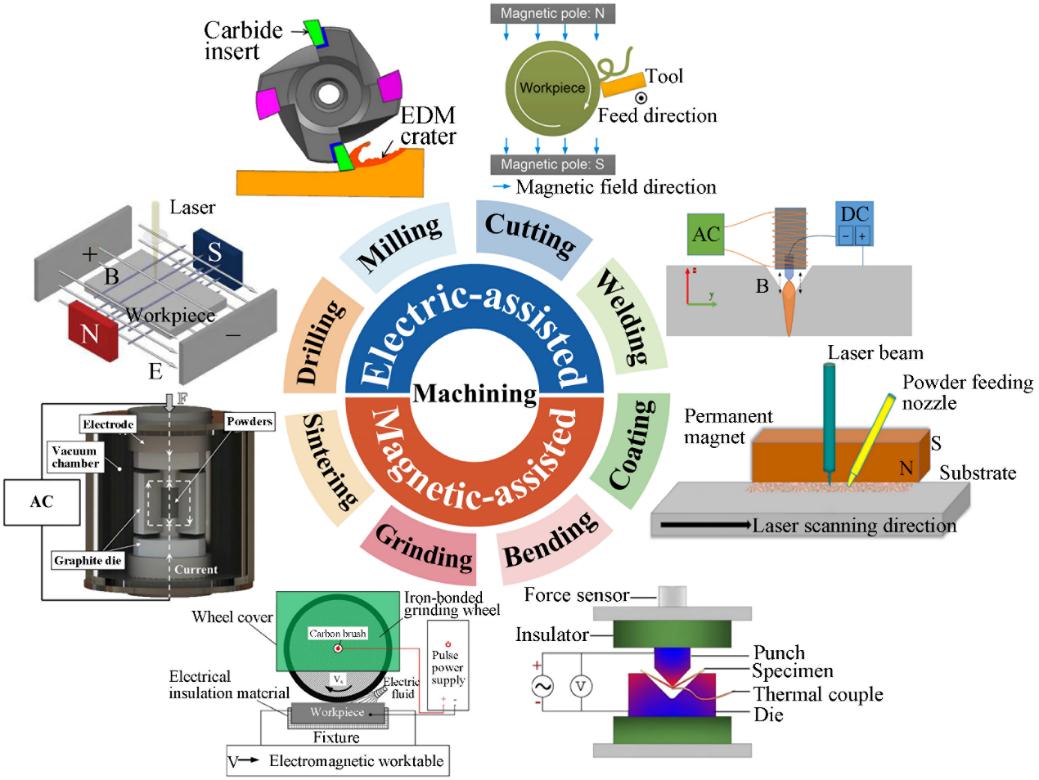

Electromagnetic treatment can significantly improve the processing performance of metal materials, not only in the plastic deformation ability, but also in key mechanical properties such as yield strength and hardness. I n terms of material processing, electromagnetic treatment technology has been successfully expanded to various processes such as cutting, grinding, drilling. welding, sintering, coating, and plastic forming, as shown in Figure 3. Electromagnetic treatment technology has been applied in material preparation, material processing, material forming. additive manufacturing and other fields.

Figure. 3 Application of electromagnetic treatment in material processing

This paper comprehensively expounds the structure-activity relationship between electromagnetic parameters, microstructure, and mechanical properties for the first time, systematically summarizes the multiple mechanisms of action, such as thermal effect, non -thermal effect, electromagnetic induction, and electromagnetic field-thermal field coupling, reveals the complexity and multi-scale and multi-dimensional characteristics of electromagnetic- material interaction, and provides theoretical guidance and technical support for the development of high-performance metal materials. The research work is supported by the National Key Research and Development Program and the National Natural Science Foundation of China.